No products

TECHNICQLL - DIY ACCESSORIES

-

CAR MAKES

- ACURA

-

ALFA ROMEO

- SPIDER Series 2 (1974-1982)

- 145 / 146 (1994-2000)

- 147 (2000-2010)

- 155 (1992-1997)

- 156 (1997-2007)

- 159 (2004-2011)

- 164 / 168 (1987-1998)

- 166 (1996-2007)

- 1750 GT Veloce (1967-1971)

- 33 (1983-1995)

- 75 (1985-1992)

- BRERA / SPIDER (2005-2010)

- GIULIETTA (2010-2019)

- GT (2003-2010)

- GTV / SPIDER (1995-2005)

- MiTo (2008-2018)

- SPIDER Series 4 (1990-1993)

- AUDI

-

BMW

- E114 (1966-1977)

- E21 (1975-1982)

- E24 (1975-1989)

- E28 (1981-1988)

- E30 (1982-1991)

- E32 (1986-1994)

- E34 (1988-1995)

- E36 (1991-1998)

- E38 (1995-2001)

- E39 (1995-2003)

- E46 (1999-2005)

- E60 E61 (2003-2010)

- E63 (2003-2010)

- E81 E82 E87 E88 (2004-2013)

- E90 E91 E92 E93 (2005-2013)

- K1300 GT (2009-2012)

- X1 E84 (2009-2013)

- X3 E83 (2003-2010)

- X3 F25 (2011-2016)

- X5 E53 (1999-2006)

- Z3 (1995-2002)

- Z4 E85 (2002-2008)

- CHEVROLET

- CHRYSLER

- CITROEN

- DAEWOO

- DAIHATSU

- DODGE

- DS

- EAGLE

- FIAT

- FORD

- GMC

- GREAT WALL

-

HONDA

- ACCORD

-

CIVIC

- CIVIC MK4 (1988-1991)

- CIVIC MK5 (1992-1995)

- CIVIC MK6 (1996-2000) Hatchback 3D / Coupe

- CIVIC MK6 (1996-2000) Hatchback 5D / Sedan

- CIVIC MK7 (2001-2005) EP2 / EP3 Si (USDM) Hatchback

- CIVIC MK7 (2001-2005) Sedan / Coupe

- CIVIC MK8 FK2 TYPE S (2006-2012) Hatchback

- CIVIC MK8 FN2 TYPE R (2006-2012) Hatchback

- CIVIC MK8 Si (2006-2012) Sedan / Coupe

- CIVIC MK9 (2013-onwards) Hatchback, Estate

- CR-V

- CRX

- HR-V

- INTEGRA

- JAZZ / FIT

- LEGEND

- PRELUDE

- S2000

- STREAM

- HYUNDAI

- INFINITI

- JAGUAR

- JEEP

- KIA

- LANCIA

- LAND ROVER

- LEXUS

- MAZDA

- MERCEDES-BENZ

- MERCURY

- MG

- MINI COOPER

- MITSUBISHI

- NISSAN

- PEUGEOT

- PLYMOUTH

- PONTIAC

- PORSCHE

- RENAULT

- ROVER

- SAAB

- SEAT

- SEAT BELT COVERS

- SKODA

- SMART

- SUBARU

- SUZUKI

- TECHNICQLL - DIY ACCESSORIES

- TOYOTA

- UNIVERSAL PRODUCTS

-

VAUXHALL / OPEL

- ASTRA F (1991-1997)

- ASTRA G / COUPE (1998-2005)

- ASTRA H (2005-2010)

- ASTRA J (2009-2015)

- CALIBRA (1990-1997)

- CORSA B (1993-2000)

- CORSA C (2000-2006)

- CORSA D (2006-2013)

- FRONTERA (1991-1998)

- INSIGNIA MK1 (2008-2016)

- KADETT E / ASTRA E (1984-1991)

- MERIVA A (2002-2010)

- MONARO (2001-2006)

- OMEGA A / CARLTON (1986-1994)

- OMEGA B (1994-1999)

- OMEGA C (1999-2003)

- SIGNUM (2003-2008)

- SINTRA (1997-1999)

- TIGRA A (1994-2001)

- TIGRA B TWINTOP (2004-2009)

- VECTRA A / CAVALIER (1988-1995)

- VECTRA B (1996-2002)

- VECTRA C (2002-2008)

- VIVARO (2001-2013)

- ZAFIRA A (1999-2005)

- ZAFIRA B (2005-2011)

-

VOLKSWAGEN

- AMAROK

- BEETLE

- CADDY

- CORRADO

- CRAFTER

- EOS

- FOX

- GOLF

- GOLF PLUS

- JETTA / BORA

- LUPO

- NEW BEETLE

- PASSAT

- PASSAT CC / CC

- POLO

- ROUTAN

- SCIROCCO

- SHARAN

- T2 (1967–1979) Transporter, Bus, Camper

- T3 / T25 (1979–1992) Transporter, Bus, Camper

- T4 (1990-2003) Transporter, Bus, Multivan, Eurovan

- T5 (2003-2015) Transporter, Bus, Multivan, Caravelle

- TIGUAN

- TOUAREG

- TOURAN

- VOLVO

Viewed products

-

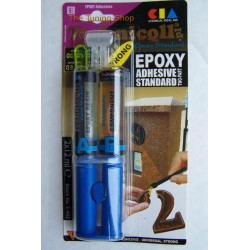

STANDARD AMBER EPOXY...

A BRAND NEW 1 x STANDARD EPOXY...

STANDARD AMBER EPOXY ADHESIVE GLUE FOR STONE METAL RUBBER WOOD MARBLE ELECTRONIC PARTS 2x12ml TECHNICQLL

E-402

New product

A BRAND NEW

1 x STANDARD EPOXY ADHESIVE GLUE FOR STONE, METAL, RUBBER, WOOD, MARBLE, ELECTRONIC PARTS etc.

Syringe 2x12ml

AMBER COLOUR

200 Items

More info

A BRAND NEW

1 x STANDARD EPOXY ADHESIVE GLUE FOR STONE, METAL, RUBBER, WOOD, MARBLE, ELECTRONIC PARTS etc.

Syringe 2x12ml

AMBER COLOUR

Standard epoxy adhesive with extended cross-linking time. Can be used for permanent connection of: glass, porcelain, ceramics, plastic (except PP, PE, PTFE), stone, concrete, marble, metals and their alloys, rubber, wood. Ideal for drowning electronic elements. It may be used as chemical anchor for parts.

PARAMETERS:

Colour: amber

Viability after mixing: 60 minutes

Initial solidification: 240 min. (in temp. 20°C)

Complete solidification: 48 h

Lap shear strength: 10.5 MPa

Temperature resistance: -30°C to 90°C

FEATURES:

- no solvents

- two-chamber syringe

- extended cross-linking time

- water and temperature resistant

- resistant against aggressive chemical factors (acids, alkalis, solvents, petrol) and consumable liquids

- high resistance against current breakdown

- when dry, it can be mechanically processed (grinding, drilling, threading)

USAGE:

Standard epoxide adhesive due to 60 minutes of lifetime after mixing the ingredients is used for repair of bigger elements, where more time for putting the adhesive in serial gluing is required. Standard epoxide adhesive is used to connect glass, wood, stones, plastic, rubber, metals, metals alloys and combinations of the above mentioned. Due to high resistance against electric breakdown and long lifetime it is used to drown electronic elements in order to protect them against moist, dust, dirt and other contaminations.

ADVANTAGES:

- safe when used

- precise dozing of ingredients, eliminates loses

- allows to completely use mixed ingredients, saturation of reinforcing net, good deaeration of the mixture

- to be used both inside and outside

- for industrial use

- for drowning electronic elements.

- allows to restore damaged threads and elements

HOW TO USE:

- Grind the surfaces to be joined with sandpaper or file.

- Remove all dirt and degrease (use Cleaning ser P-102 or Technical degreaser P-959).

- Extract the proper amount of ingredient and precisely mix to receive homogeneous colour.

- Put prepared mixture onto one of the surfaces.

- Press the elements strongly and keep fixed till the adhesive is completely hardened.

TIPS AND RECOMMENDATIONS:

TIPS AND RECOMMENDATIONS:

- - heat the product to room temperature prior to mixing the ingredients

- - do not mix A and B ingredients more, than can be used within 60 minutes (lifetime)

- - repair time can be shortened by directing the hot air flow to the joint

- - do not use to connect/ fill in PP, PE and PTFE.

STORAGE:

STORAGE:

Store in temperature from 5°C to 25°C. Protect against moisture.